Dr. Mukul Chandra Bora, M.Tech (IIT-KGP), Ph.D. (IITG), FIE (IN), MISTAM (IN)

State Project Administrator, State Project Implementation Unit – North East

(A unit of MHRD in Technical Education, Government of India)

Centre for Educational Technology, Indian Institute of Technology, Guwahati

Phone No: 0361-2583016/3010

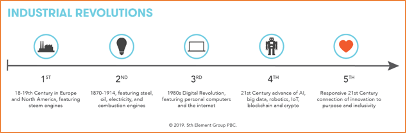

At the very outset and before going to the detailed discussion on the Industry 4.0, we must first understand the chronology and scientific definition of Industrial revolution which is defined as the changes have taken place in manufacturing and transportation of man and materials and began with the changes in the process of fewer things that were made manually or by hand and then manufactured by using machines in larger-scale factories. During this period of time, the manufacturing of goods moved from small shops and homes to large factories which in turn brought changes in the culture of human life to move from rural to nearby big cities in search of employment. The first Industrial Revolution was started in the year 1765 when agricultural societies became more industrialized and then followed by interstate or intercontinental railroad (due to discovery of Steam Engine, 1698), the cotton gin (a machine that quickly separates cotton fibers from their seeds), electricity and other technological inventions permanently changed the society throughout the world. The Industrial Revolution which has taken place in the world till today are the three industrial revolutions that transformed our work culture and livelihood along with the process of manufacturing, transportation as well as the production of goods for our daily life. It is to be noted that these Industrial Revolution not only change our living and work culture but also transformed the entire economy from agro and handicrafts based on economies of large-scale industries, mechanized manufacturing, and the system of a manufacturing hub. The invention of modern machines, new power sources, and new ways of organizing work made existing industries more productive and efficient and with each of these three advancements—the steam engine, the age of science and mass production, and the rise of digital technology—the world around us fundamentally changed and it is happening for the fourth time in the area of Industrial Revolution. Before going to Industry 4.0 let us have a look briefly at the different Industrial Revolution taken place throughout the world.

The first Industrial Revolution has started long back in the year 1765 was the proto-industrialization period and started at the end of the 18th to the beginning of the 19th century which brought a lot of changes in the industries in the form of mechanization and mechanization was the only reason why agriculture started to be replaced by the industry as the backbone of the societal economy. During this period of time, people witnessed massive extraction of coal along with the steam engine and was the main reason for the creation of a new type of energy that later on helped speed up the manufacturing of railroads thus accelerating the economy.

The Second Industrial Revolution has started way back in 1870 following the first and almost a century with massive technological changes/advancements in the field of industrialization and brought a new source of energy like Electricity, Gas, and Oil. This revolution, in turn, leads to the manufacturing of the internal combustion (IC) engine that reached its full potential of application for human life. The major changes brought by this revolution other than IC Engine are steel demand, chemical synthesis, and methods of communication such as the telegraph and telephone. In the end, the inventions of the automobile and the Aircraft come into play and that is the reason why the Second Industrial Revolution is considered the most important time of revolution throughout the world.

The third Industrial Revolution has started in 1969 nearly after one century in the second part of the 20th century with the invention of another untapped energy source which is called Nuclear energy. The third revolution has given us revolutionary changes in the frontier areas of electronics, telecommunications, and computers or computing technology which we are very much acquainted by us as on today and with the help of these new technological inventions opened some new avenues in the frontier areas like space exploration and research, rocket sciences, and biotechnology. In the later part of these revolutions, the inventions of Programmable Logic Controllers (PLCs) and Robots has brought us to an era of high-level automation in the industries throughout the world.

Fourth Industrial Revolution or Industry 4.0 which is commonly used terminology has derived from the German term ‘Industrie 4.0’ which refers to the intelligent networking of machines and processes for industry with the help of information and communication technology. The first official starting of Industry 4.0 has taken place in Germany with the high-tech strategy to transform German manufacturing with the use of Information and Communication Technology (ICT) with great emphasis on production, people, environment, and security. The Industry 4.0 as a revolution is a revolution happening right now and are experiencing it every day without knowing its actual magnitude of operation in manufacturing.

The starting of Industry 4.0 can be visualized by us with the use of the Internet in our daily life and brings the technological phenomenon called as virtual reality in which we are living with during this Pandemic called as COVID-19 and we would not have seen the use of ICT technology in our Education i.e., Teaching and Learning. Industry 4.0 has got three distinctions from the earlier industrial revolution in terms of velocity, scope, and systems impact. The speed of current breakthroughs has no historical precedent and when compared with previous industrial revolutions, this is evolving exponentially rather than a linear pace and will disrupt almost each and every industry throughout the world. The breadth and depth of these changes herald the transformation of entire systems of production, management, and governance in the industries to a great extent. The figure below will show the process of the Industrial Revolution throughout the world.

Source: Google (Copyright@ 5th Element Group, PBC, 2019)

Source: Google (Copyright@ 5th Element Group, PBC, 2019)

According to a report published by World Economic Forum (WEF) in the year 2016, it was reported that there will be 133 million new jobs that will be required for Industry 4.0 with a net creation of growth of 68 more jobs in the different areas of ICT. This will go to affect the job and skill market in the following ways:

- Skills and jobs displacement will affect every industry and geographical region, but losses can be offset by job growth in key areas.

- A clear majority of businesses believe that investing in skills, rather than hiring more short-term or virtual workers, is the key to successfully managing disruptions to the labor market for the long term.

- The new research by the World Economic Forum is the first of its kind, representing more than 13 million employees in nine industry sectors and 15 economies; it aims to guide business and policy-makers on how to equip labor forces with the skills to navigate the disruption of the Fourth Industrial Revolution.

- The digital revolution is changing how we live and work.

In this present industrial revolution, the industry and business are being transformed by a new wave of digital technology and the mobile sensors can track inventory from the manufacturing floor, all the way through the shipping channel, to a retail shelf or a customer’s door. The manufacturing machines send alerts about quality control, errors, supply shortages or breakdowns and simultaneous use of predictive software will automatically schedule for periodic maintenance for trucking fleets based on travel data and past repair timelines. The Behavioural analytics inbuilt with Industry 4.0 will help financial institutions to spot suspicious activity in bank and credit card accounts. All the activities cited above will be make enabled by various technologies viz., Mobile, Cloud computing, Data Analytics (DA), Automation, Artificial Intelligence (AI), the Internet of Things (IoT), 3D printing, Robotics and Augmented and Virtual reality (AR/VR). These types of intelligent and interconnected ecosystems will be the major driver for the fourth industrial revolution and this potent combination of technologies will enhance the accuracy, efficiency, productivity, and personalized customer service to business and industry in unprecedented ways besides lowering the cost of doing business. According to a study conducted by Accenture (2017) and McKinsey Global Institute, an average U.S. Company could save $85,000 per employee via the integrated deployment of said technologies and intelligent automation could save employers a staggering $15 trillion in wages by 2030 worldwide. This huge savings on employment will give rise to many questions on employment and upcoming scenario on the issue of educated youth not only for our country but for the whole world and the pertinent question of today is the effect of Industry 4.0 on the job market.

It is further reported that about half of the activities that people are paid to do globally could theoretically be automated using currently demonstrated technologies and between 400 and 800 million current occupations could be displaced by 2030 as per a study conducted by the McKinsey. In the same studied it is further stated that the jobs involving physical labor, data collection/processing, manufacturing, retail, and accommodation/food services will be most the most vulnerable during the shift to Industry 4.0. But when we widen our eyes, it actually appears far brighter and we could expect eight to nine percent growth in the labor market by 2030 and this will be new types of occupations that have not existed before.

This is not the first time we have heard about the loss of job and heard several times in the history of the Industrial Revolution including the early 1980s when an electronic gadget called the personal computer swept into homes and offices and transformed the whole work environment in the entire world. It is estimated that from 1980 – 2015, the introduction of the PC displaced about 3.5 million jobs in the U.S. and created new jobs in the tune of 19.2 million, and industry experts believe that similar spinoff of employment growth from Industry 4.0. According to the WEF report (2018 Future of Jobs), strong employment growth is predicted not only in emerging sectors like Artificial Intelligence (AI), Robotics, and Block-Chain but also in non-tech positions such as customer service, sales, marketing, training, and skills development.

The following to the sectors which may be affected due to Industry 4.0 as per report (2013) published by the Oxford University and there is a chance of 98-99% chance of being automated out of around 700 occupations. They are viz., Telemarketers, Title Examiners, Abstractors, and Searchers, Sewers, Hand, Mathematical Technicians, Insurance Underwriters, Watch Repairers, Cargo and Freight Agents, Tax Preparers, Photographic Process Workers and Processing Machine Operators, New Accounts Clerks, Library Technicians, Data Entry Operators, Timing Device Assemblers and Adjusters, Insurance Claims and Policy Processing Clerks, Brokerage Clerks, Order Clerks, Loan Officers, Insurance Appraisers, Auto Damage, Umpires, Referees, and Other Sports Officials, Tellers, Etchers and Engravers, Packaging and Filling Machine Operators and Tenders, Procurement Clerks, Shipping, Receiving, and Traffic Clerks, Milling and Planning Machine Setters, Operators, and Tenders, Metal and Plastic, Credit Analysts, Parts Salespersons, Claims Adjusters, Examiners, and Investigators, Driver/Sales Workers, Radio Operators.

On the other hand, the list of 30 most safe occupations with a 0.66 percent or less probability of being computerized based on current technology are viz. Recreational Therapists, First-Line Supervisors of Mechanics, Installers, and Repairers, Emergency Management Directors, Mental Health and Substance Abuse Social Workers, Audiologists, Occupational Therapists, Orthotists and Prosthetists, Healthcare Social Workers, Oral and Maxillofacial Surgeons, First-Line Supervisors of Fire Fighting and Prevention Workers, Dieticians and Nutritionists, Lodging Managers, Choreographers, Sales Engineers, Physicians and Surgeons, First-Line Supervisors of Transportation and Material-Moving Machine and vehicle operators, Instructional Coordinators, Psychologists, All Other, First-Line Supervisors of Police and Detectives, Dentists, General, Elementary School Teachers, Except Special Education, Medical Scientists, Except Epidemiologists, Education Administrators, Elementary and Secondary School, Podiatrists, Clinical, Counselling, and School Psychologists, Mental Health Counsellors, Fabric and Apparel Patternmakers, Set and Exhibit Designers, Human Resources Managers and Recreation Workers.

The most optimistic view predicts that Industry 4.0 will bring new markets, more opportunities and takes more effects into consideration than only the effect of substituted jobs and the other effects like product demand actually might contribute to increase demand for employees on the market. But the skills that were required in 2015 will not be required by 2020 to make someone employable and the skills such as creativity, complex problem solving, critical and innovative thinking as well as social and cognitive skills will play an important role in the employability of the students. So to increase the employability of students and educated youth the need of skilling and reskilling would be immense importance for the educational Institutions to be survived in the 21st century.

It is important to note that the Industrial Revolution is a dynamic process in the area of industrialization and is going to change from time to time as per the need of the hour. So here are some of the highlights of the 5th Industrial Revolution which going to happen soon in this fast-changing, technologically driven industrial world. There was an event held at Davos in the year 2019 with the organizational support from Forbes, MIT, and Tata, to formulate the outline of this forthcoming revolution wherein it was concluded that in this 5th Industrial Revolution both the humans and machines will work together metaphorically and the theme is stated as “Blockchain+AI+Human=Magic”. This equation seems impossible to some, but it can, and will, prove true and AI (Artificial Intelligence) will help to increase human productivity. The use of Blockchain will help give access to banking (and intangible forms of capital) to the unbanked and Robots will help humans align returns on investment (ROI) with purpose but need more clarity for its implementation in real-time industries. So we have to keep in our mind that we have to change our work culture and Engineering Education as per the need of the industries otherwise we will be able to produce only unemployed educated in this country.

This is an alarming situation for all the educationist of this state in particular and the country in general to change our behavior towards teaching the technological subjects as per the need of the technologically driven development. If we fail to fulfill our commitment towards student demand-driven education then it will make all of us accountable and the policy of the Government is very much clear in this regard. So this is the time for all the teaching communities to work hard to understand the demand of the student community otherwise the days are not far when teachers will be worst affected by this Industrial Revolution.

ছাৰ ৰ কথাবোৰৰ যুক্তি খুৱেই শক্তিশালী , লিখনি টো পঢ়িলো । কথাবোৰ চৰকাৰে বুজিব কেতিয়া । জনা মানুহখিনি ক লগত লৈ হে চৰকাৰ চলিব লাগে ।

Sir waste management r uporot likhibo sun

Informative article sir… আপোনাৰ yoga ৰ লিখনী টো ও ভাল লাগিছিলে..